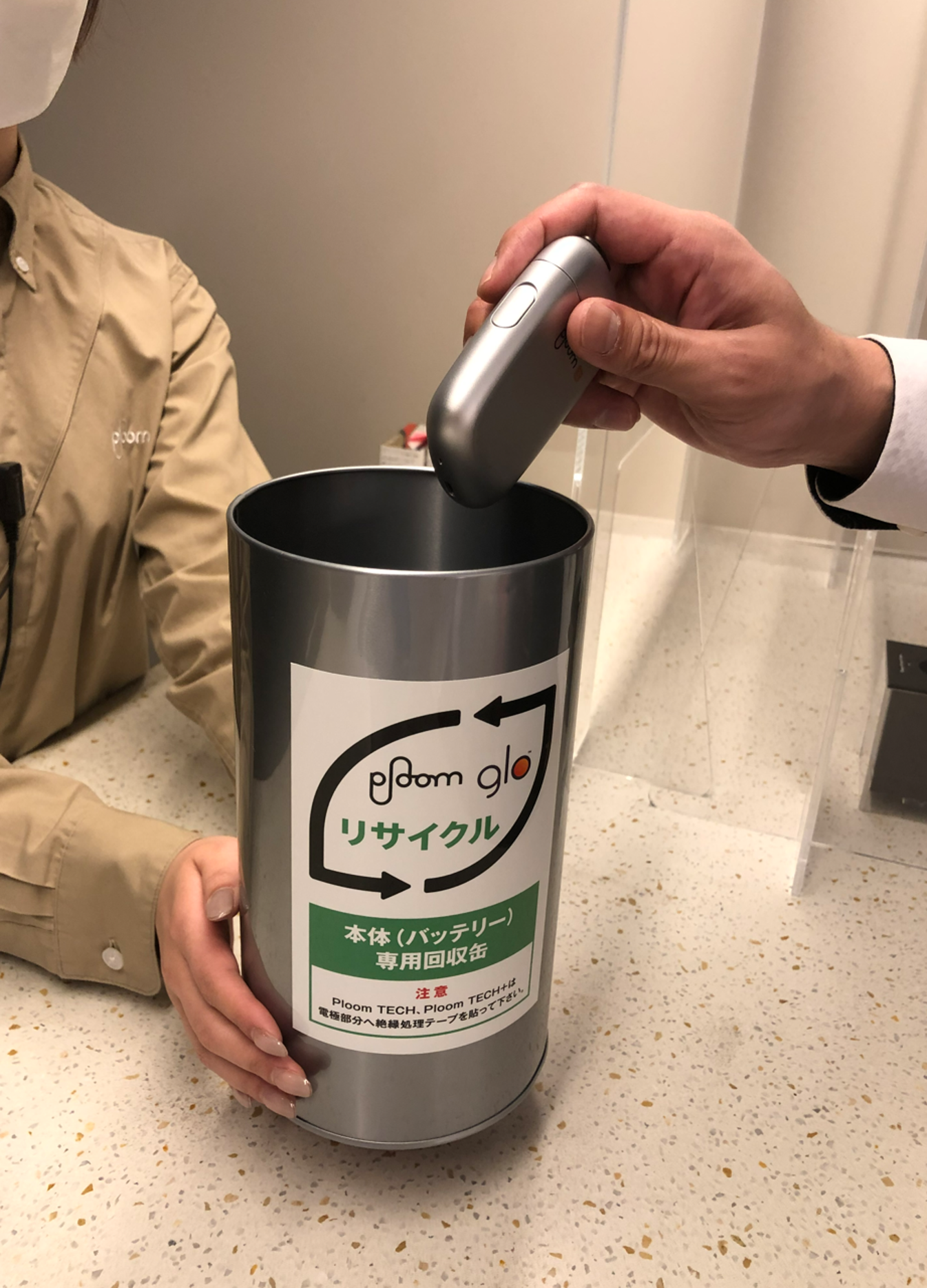

In Japan, we launched a program in 2019 to collect used Ploom devices, capsules and cartridges via convenient collection boxes at around 300 shops in Tokyo. In 2020, this program was extended to include additional tobacco players and it was launched throughout Japan in 2021. Since then, around 1,100 collection points have been established in all 47 prefectures.

See the JTI website for information on initiatives in the tobacco business.

Environment and our operations

Waste, Packaging & Circularity

Waste Reduction

With a high level of concern from society and stakeholders regarding waste such as plastic, we recognize this as an important issue that should be addressed from the perspective of the JT Group’s business activities.

Across the JT Group, we apply a “reduce, reuse, recycle” approach as the basis of our waste management, and waste management is one of the JT Group Sustainability Targets.

We aim to achieve zero factory waste to landfill by 2030 in our tobacco business. In addition, our tobacco business will engage trade and consumers on responsible disposal of devices through take-back schemes for Ploom, and through anti-littering campaigns for consumables. In our processed food business, we will pursue waste reduction to contribute to a circular society and will aim to recycle 95% of all waste from its Japanese offices (excluding heat recovery).

Progress toward quantitative targets

By the end of 2024, 8% of total factory waste was landfilled. We continue launching take-back schemes for Ploom devices in markets we operate in. We also promote anti-littering awareness for consumables through targeted campaigns.

The waste-recycling rate at processed food business sites in Japan was 91%, and we will continue to promote appropriate initiatives based on trends in recycling-related technology.

Designing for circularity - Packaging, products and devices

It is essential for our business operations that we work to reduce environmental impacts arising from our products, including the impact of waste in the downstream value chain. Moreover, we believe that these initiatives are in line with consumer expectations and that they promote sustainable business operations.

We will reduce our packaging (including plastic) and ensure that the remaining is 88% reusable or recyclable by 2025, and 100% by 2030. Our tobacco business will reduce packaging and achieve 85% recyclability by 2025, rising to 100% by 2030. In total, recycled content will account for 20% of our tobacco business packaging by 2025.

We also aim to reduce the environmental impact of our products by further reducing the amount of virgin plastic used, and by utilizing recyclable devices and plant-derived organic resources.

Progress toward quantitative targets

By the end of 2024, the rate of use of reusable or recyclable packaging materials was 92% for the JT group as a whole and 91% for the tobacco business. The rate of use of recycled materials in the total weight of packaging materials was 17%.

RRP return/collection scheme

In 2019, we published company-wide internal guidelines for RRP waste management and recycling. These guidelines help markets to determine and implement appropriate initiatives.

We encourage consumers to recycle or dispose of our RRP products safely. In some markets we offer return schemes adapted to local needs.

Case study

Ploom - Return scheme in Japan

Case study

Biomass plastic as a raw material for the packaging

A by-product of rice milling is crushed rice: rice that is broken during the milling process and can no longer be used for manufacturing. In a first for the industry, we are now using the domestic carbon-neutral biomass plastic RiceResin®*, which contains 10% crushed rice generated by our Group, as a raw material for the packaging of some of our cooked rice products. In addition to using RiceResin®, we have reduced the amount of petroleum-based plastic in our packaging by around 4.2% compared to conventional products. We have done this by making the exterior film even thinner.

- * RiceResin® is a registered trademark of Rice Resin inc. Old rice that is not edible and crushed rice generated during rice milling are upcycled into plastic using new technology.

See the JT website for information on initiatives in the processed food business.