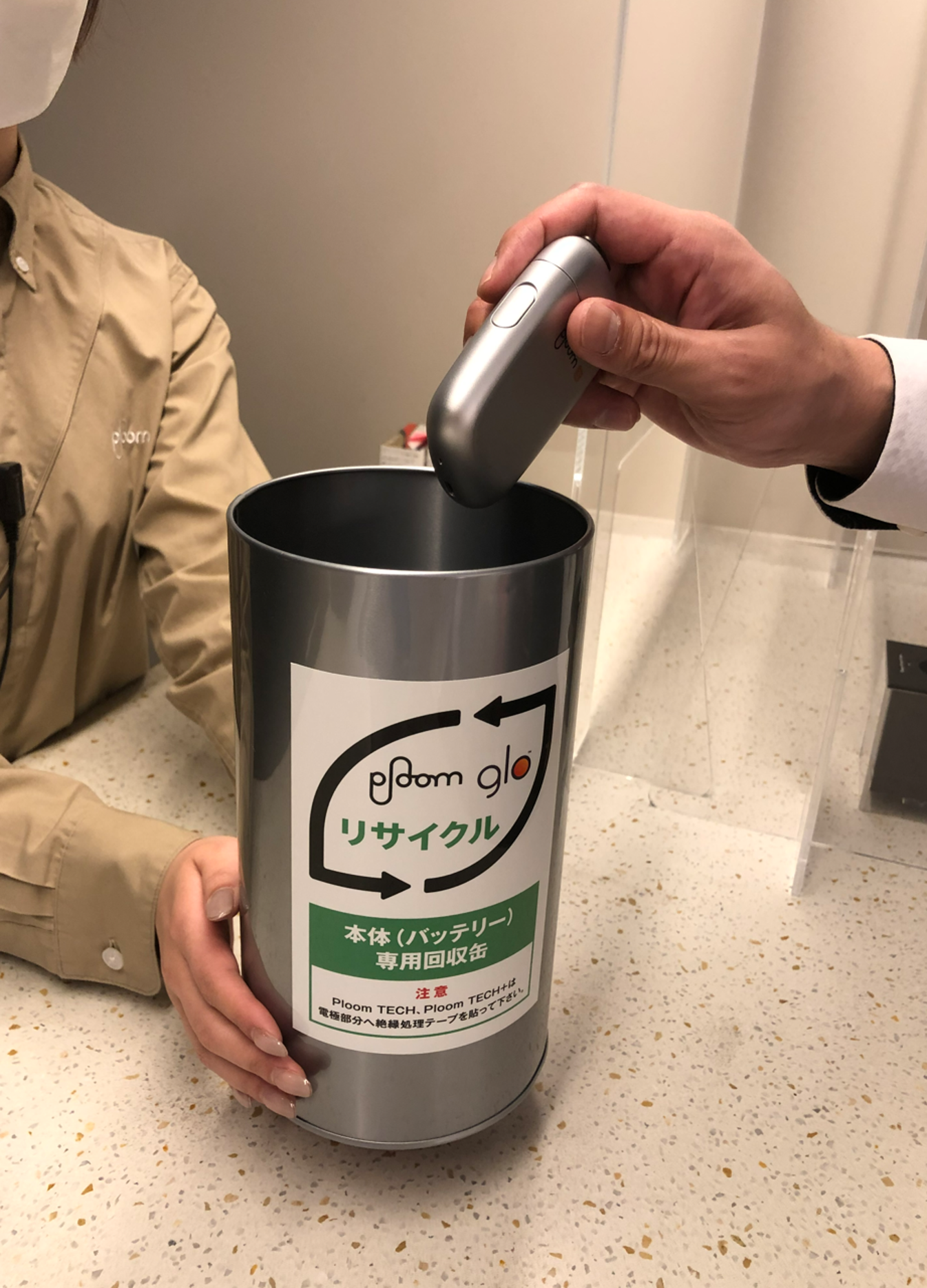

In Japan, we launched a program in 2019 to collect used Ploom devices, capsules and cartridges via convenient collection boxes at around 300 shops in Tokyo. In 2020, this program was extended to include additional tobacco players and it was launched throughout Japan in 2021. Since then, around 1,200 collection points have been established in all 47 prefectures.

Product stewardship, circularity and waste

We are committed to achieving continuous improvement in the sustainability of our products and packaging.

In 2022 we introduced a new sustainability governance model with a focus on product stewardship, circularity and waste. It aims to manage the safety and the environmental and social impacts of our products and their packaging at all stages of their life cycle - and to avoid waste through product circularity or reduce it by operating an effective waste management system.

We will reduce our packaging (including plastic) and ensure that the remaining is 88% reusable or recyclable by 2025, and 100% by 2030. Our tobacco business will reduce packaging and achieve 85% recyclability by 2025, rising to 100% by 2030. In total, recycled content will account for 20% of our tobacco business packaging by 2025.

Read more about product stewardship, circularity and waste on JT International sustainability website.

RRP return/collection scheme

In 2019, we published company-wide internal guidelines for RRP waste management and recycling. These guidelines help markets to determine and implement appropriate initiatives.

We encourage consumers to recycle or dispose of our RRP products safely. In some markets we offer return schemes adapted to local needs.

Case study

Ploom - Return scheme in Japan

Case study

Biomass plastic as a raw material for the packaging

A by-product of rice milling is crushed rice: rice that is broken during the milling process and can no longer be used for manufacturing. In a first for the industry, we are now using the domestic carbon-neutral biomass plastic RiceResin®*, which contains 10% crushed rice generated by our Group, as a raw material for the packaging of some of our cooked rice products. In addition to using RiceResin®, we have reduced the amount of petroleum-based plastic in our packaging by around 4.2% compared to conventional products. We have done this by making the exterior film even thinner.

- * RiceResin® is a registered trademark of Rice Resin inc. Old rice that is not edible and crushed rice generated during rice milling are upcycled into plastic using new technology.

Various information on Environment and our product can be found at the followings.

For the goals set forth in the Tobacco Business Sustainability Strategy, Read about Product stewardship, circularity and waste (Environment).